- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 260 Author: Site Editor Publish Time: 2023-03-06 Origin: Site

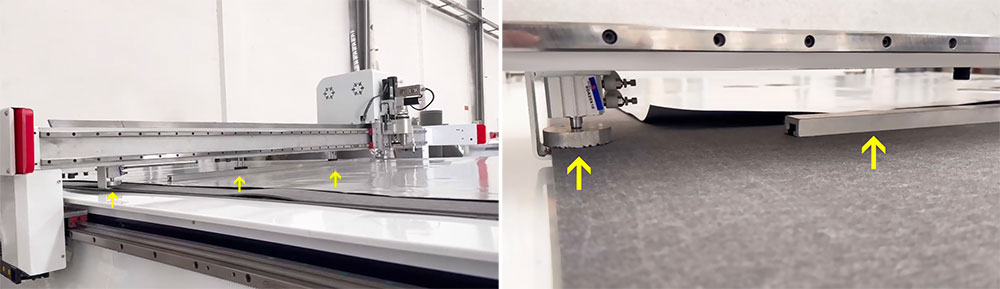

CNC Oscillating Knife Cutting Machine With Auto Feeding Converyor

There are two types of tables for the oscillating knife cutting machine: fixed tables and automatic feeding tables.

The fixed table cannot be moved. It's suitable for cutting sheets. The automatic feeding table is mainly used for cutting the roll material.

Many materials such as leather, cloth, carbon fiber, rubber, etc are in roll.

Working process of the automatic feeding table.

1. First put the roll material on the holder behind the machine. This allows the material to be easily rotated and unfolded.

2. Spread the front of the material to the rear of the CNC oscillating knife cutting machine.

3. Start the feeding table, the feeding table rolls forward, and the material moves forward to spread on the working table of the machine.

4. Import the cutting graphics to the automatic cutting machine, and start the machine to start working.

5. The machine will cut, feed the material automatically, and continue cutting. Until the imported cutting graphics are cut or the set number of repeated cutting is finished.

The structure and principle of the automatic feeding table.

1. The automatic feeding table is a rolling table. The rolling table is a ring of soft felt. There is a roller at the front and back. The felt rotates around these two rollers during automatic feeding.

2. Two cylinder clips are installed on both sides of the working beam. When feeding automatically, two clips hold the two ends of the felt. Then the crossbeam moves forward, drags the felt to roll forward, and brings the material forward.

3. The rear side of the beam is equipped with a pressing rod. When feeding automatically, the pressing rod and two clamps fall down at the same time to hold down the material. Make sure the material doesn't slip when pulling the material forward.

4. After feeding, the clamps and pressing rods on both sides are released at the same time. The machine then proceeds to cut.

Advantages of automatic feeding table

1. The automatic feeding table saves labor. No manual pulling is required. Reduced labor intensity and reduced labor costs.

2. Save time. Automatically pull material after cutting. The whole cutting process does not stop. Moreover, the pulling speed of the machine is much faster than that of manual pulling. Moreover, the material is very flat after being fed by the machine, and the material drawn by hand is easy to skew, fold, etc.

3. Save material. Automatic feeding automatically determines the length of feeding, basically no material waste. If the material is pulled manually, it is difficult to guarantee the length of the material pulled forward each time. If the length of the material is too long, the material will be wasted. If the length of the material is short, the cut pieces cannot be used.

welcome to contact us and learn more about the CNC oscillating knife cutting machine.